Spin Coating products are manufactured by treating the surface of substrates with electrochemical etching technology, then applying a fluororesin coating that provides excellent corrosion and heat resistance.

These products are supplied in sheet form after coating, allowing customers to apply them to various product shapes as needed. They can also be freely processed through deep drawing and other forming operations.

Unlike most coating systems that require primer coating, this product achieves adhesion through an anchoring effect instead of chemical bonding by primer. This results in superior durability, corrosion resistance, and excellent adhesion even after deep drawing.

Furthermore, various physical properties (adhesion, abrasion resistance, corrosion resistance, elongation, etc.) are tested with specialized equipment and expertise according to KS and JIS standards, ensuring stable product quality without requiring additional customer investment in testing or equipment.

01. Safety

Adhesion of the coating is ensured without the use of non-ionic resins, guaranteeing safety.

No heavy metals (lead, cadmium, mercury), no PFOA, biphenyl, benzene, bisphenol, or dioxins → no environmental hormone concerns.

The coating components are high molecular compounds that are not absorbed in the digestive system but excreted.

(icons) ✅ PFOA FREE / ✅ LEAD FREE / ✅ CADMIUM FREE

02. Heat Resistance

Passed heat resistance test at 340℃ for 4 hours in a hot-air circulation furnace.

03. Scratch Resistance

Maintains surface durability and appearance even after cleaning with a steel scrubber.

04. Abrasion Resistance

Passed reciprocating abrasion test up to 20,000 cycles.

05. Corrosion Resistance

Secured corrosion resistance of over 500 hours in a salt spray test.

(Comparison photos: conventional spray coating vs spin coating).

06. Additional Testing (Cooking Oil Test)

Coating maintains properties and performance even after repeated heating and cooling of cooking oil.

Durability → Passed more than 5,500 test cycles.

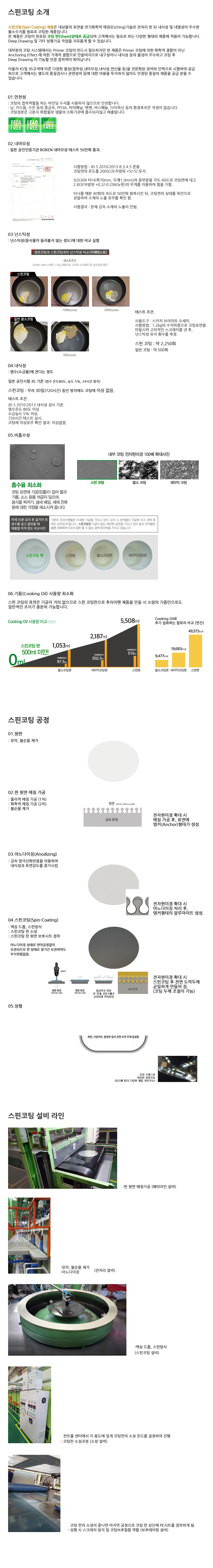

Spin Coating Process

Pre-treatment (surface etching)

Anchoring

Spin Coating

Drying & Curing

Spin Coating Production Line

Automated loader and pre-treatment facilities

Large-scale drying and curing ovens

Automated spin-coating machines

Quality control equipment (QC devices)

Automated transfer lines for improved production efficiency